-

Raw Material Collection

We begin by sourcing clean, waste cotton rags from textile industries. These rags are carefully sorted to ensure the best quality for pulping.

-

Pulping

The cotton rags are cut, softened, and beaten into fine pulp using traditional and eco-friendly techniques — without the use of harmful chemicals.

-

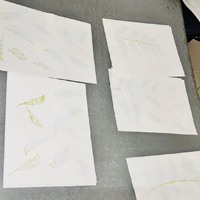

Sheet Formation

Our skilled artisans dip wooden frames into the pulp mixture, forming each sheet by hand. This step requires precision, patience, and craftsmanship passed down through generations.

-

Drying & Pressing

The wet sheets are carefully transferred to cloth and sun-dried or press-dried, depending on the paper type. This natural drying process ensures strength and softness.

-

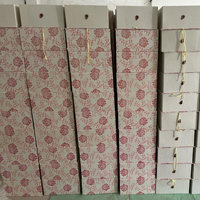

Finishing & Customization

Each sheet is trimmed, polished, and can be dyed, printed, textured, or customized as per customer needs — ideal for stationery, packaging, and gift paper.

-

Quality Check & Packaging

Every batch goes through a strict quality check before being carefully packed for delivery, ensuring perfection in every sheet that reaches you.